Protein X-ray Crystallography and Automation

Advances in X-ray Crystallography for Protein Structure Determination

Automated Liquid Handling Platform

The Bravo Automated Liquid Handling Platform is a robotic high-performance, compact, and versatile liquid handler that automates various laboratory tasks, such as pipetting, dispensing, and sample preparation. Its compact design makes it suitable for use in standard lab environments, including biosafety cabinets. The system supports a wide range of plate formats and volumes, making it a flexible tool for diverse workflows.

Key Features

Compact Design:

- Small footprint, ideal for use in laminar flow hoods and biosafety cabinets.

Precision and Accuracy:

- High precision in liquid dispensing, even at low volumes.

Scalability:

- Supports various microplate formats (96-well, 384-well, and 1536-well plates).

- Accommodates different liquid volumes, from microliters to milliliters.

User-Friendly Software:

- Operated using Agilent VWorks automation control software, which offers intuitive programming and workflow customization.

Flexible Deck Configuration:

- Multiple deck positions allow for diverse configurations to support specific workflows.

Compatibility:

- Works with a variety of labware, including tubes, reservoirs, and plates.

HEPA Filter Option:

- Provides a clean working environment for contamination-sensitive applications.

Automation Integration:

- Can be integrated with other laboratory instruments for high-throughput workflows.

Applications

Genomics:

- DNA/RNA extraction and purification.

- PCR setup and qPCR reaction preparation.

Proteomics:

- Protein crystallization.

- ELISA and other immunoassays.

Drug Discovery:

- High-throughput screening (HTS).

- Compound management and serial dilutions.

Cell Biology:

- Cell seeding and media exchange.

- Assay development and screening.

Analytical Chemistry:

- Sample preparation for chromatography or mass spectrometry.

- Dilution and mixing protocols.

Next-Generation Sequencing (NGS):

- Library preparation and normalization.

- Bead-based cleanup and size selection.

Liquid Dispenser

The CERTUS FLEX Micro Dispenser is an advanced, piezoelectric-driven dispensing system capable of handling small liquid volumes with exceptional accuracy and repeatability. It is designed for non-contact dispensing, ensuring contamination-free operation and precise control over the dispensed volume, even at micro- and nano-liter scales.

Key Features

High Precision and Accuracy:

- Dispenses liquid volumes in the range of nano-liters to micro-liters.

- High repeatability with minimal deviation in dispensed volumes.

Non-Contact Dispensing:

- Reduces contamination risks.

- Suitable for applications requiring sterile or cleanroom conditions.

Wide Range of Liquids:

- Handles a variety of liquids, including viscous solutions, biological samples, and reagents.

Flexible Integration:

- Compact design for easy integration into automated systems or laboratory workflows.

Fast Dispensing:

- Capable of high-speed dispensing for time-sensitive processes.

Customizable Parameters:

- Adjustable dispensing settings to suit specific applications or liquid properties.

Durable and Reliable:

- Built for long-term use with minimal maintenance.

Applications

Life Sciences and Biotechnology:

- Dispensing reagents, enzymes, or cells in microplates for high-throughput screening.

- Preparing PCR reactions or sequencing samples.

- Spotting DNA, RNA, or proteins onto substrates for bioassays.

Pharmaceutical Industry:

- Precision dosing in drug discovery and development.

- Dispensing active pharmaceutical ingredients (APIs) for formulation studies.

Electronics Manufacturing:

- Application of adhesives, coatings, or solder paste in small, precise amounts.

Diagnostics:

- Filling cartridges or microfluidic devices with reagents.

- Dispensing samples for clinical testing.

Research and Development:

- Experimentation requiring precise liquid handling at small scales.

Food and Beverage:

- Precise dosing of additives or flavors in product development.

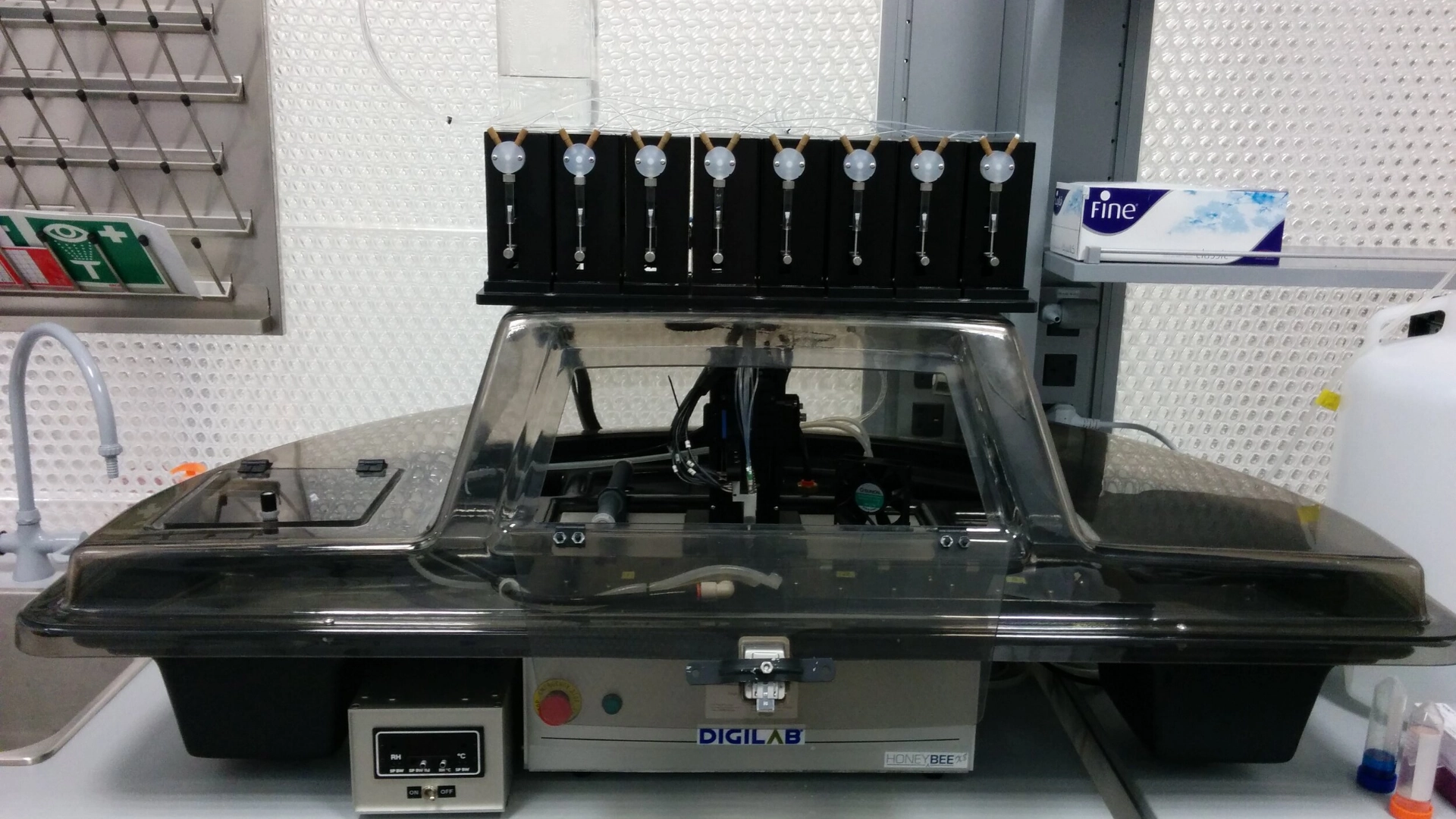

Protein Crystallization Robot

The HoneyBee X8 is a high-speed protein crystallization robot designed to automate and streamline the setup process for protein crystallization experiments. It is specifically designed for use in laboratories where high-throughput and precision in protein crystallization are required, such as structural biology and pharmaceutical research. The device utilizes nanoliter dispensing volumes, which is crucial for performing experiments with small amounts of precious protein samples.

Key Features

Eight Channels for Dispensing:

The HoneyBee X8 has eight independent dispensing channels that allow simultaneous preparation of multiple crystallization conditions on different plates. This parallel capability increases throughput and efficiency.Precise Nanoliter Dispensing:

The system is capable of dispensing protein and reagent solutions in nanoliter volumes, which is important for optimizing crystallization conditions while minimizing the amount of precious protein required.High-Speed Operation:

It offers fast setup times, making it suitable for high-throughput screening. This is particularly advantageous when testing numerous crystallization conditions for different proteins.Automated Liquid Handling:

The HoneyBee X8 automates the entire process of setting up crystallization trials, reducing the need for manual pipetting and human error.Advanced Software Integration:

It comes with dedicated software that allows for easy programming, control, and tracking of experiments. The software can also be used to analyze and optimize crystallization setups.Compatibility with Commercial Crystallization Plates:

The device is designed to work with a variety of commercially available crystallization plates, which are standardized in the field, ensuring that experiments are compatible with a wide range of protocols.Versatility in Experimental Setup:

The HoneyBee X8 can be used with various crystallization techniques, such as sitting-drop, hanging-drop, and microbatch crystallization, providing flexibility in experimental design.

Applications

Protein Crystallization:

The primary application of the HoneyBee X8 is to automate the protein crystallization process, which is a critical step for obtaining high-quality crystals required for X-ray crystallography. This is especially important in structural biology, where understanding the three-dimensional structures of proteins is crucial.High-Throughput Screening:

The HoneyBee X8 enables high-throughput screening of crystallization conditions, allowing researchers to test a wide variety of conditions quickly and efficiently. This is important in finding the optimal crystallization conditions for a given protein.Structural Determination by X-ray Crystallography:

Protein crystallization is an essential first step in X-ray crystallography, a technique used to determine the tertiary structure of proteins. The HoneyBee X8 is used to prepare crystallization plates with high precision, making it possible to obtain high-quality protein crystals suitable for X-ray analysis.Drug Discovery and Development:

By facilitating the study of protein structures, the HoneyBee X8 is useful in drug discovery. High-quality protein crystals are necessary for understanding how drugs interact with their target proteins, which is essential in designing new therapeutics.Enzyme and Antibody Production:

In the study of enzymes or antibodies, protein crystallization is essential to determine their 3D structure. The HoneyBee X8 can be used in the production and characterization of enzymes and antibodies in research and commercial settings.Academic and Pharmaceutical Research:

This device is widely used in academic research settings for protein structure studies, as well as in pharmaceutical companies involved in drug development, where protein crystallization plays a key role in the determination of target structures for therapeutic intervention.